This post will attempt to answer that tricky perennial question around birthday and Christmas time – which is the best digger present to get?

Of course, it all depends on the age of the child (or adult) the gift is for. Though we all love diggers, different age groups like and expect different things in a toy.

Let’s start with the youngest first. Our top recommendation for a present for preschool kids is without doubt Dexter the Digger by Wow Toys. The manufacturer recommends this particular toy for children from one and a half up to the age of five years, but let’s not kid ourselves, many older kids will love playing with this too.

Let’s start with the youngest first. Our top recommendation for a present for preschool kids is without doubt Dexter the Digger by Wow Toys. The manufacturer recommends this particular toy for children from one and a half up to the age of five years, but let’s not kid ourselves, many older kids will love playing with this too.

Dexter is a superbly robust digger that will resist the fiercest mishandling. His friendly face and rounded edges make him the most tactile of all the toys listed here. He comes with great fun accessories including a driver that easily slots into the cab and some plastic boulders for scooping up. Dexter makes for a very exciting present as wrapped up he makes an extremely large gift indeed.

For slightly older kids the best gift would have to be the Bruder Toys JCB 4CX. No child would be disappointed with the size of this present – the box it comes in measures a whopping 50 centimetres across and 20 cm high. Only trouble is, you might need to get a bigger Christmas tree to put it under!

The JCB 4CX is a classic, iconic digger. Unlike Dexter’s kiddy-styling Bruder pride themselves on making robust and accurate scale toys. Bruder’s 4CX is a superb blend of kid-tough and realistic digger styling which all helps it stand up to the most ruthless play imaginable. In short, it looks great, plays great and makes a great gift.

If you’re not quite ready to commit to the mighty 4CX, Bruder do have a smaller (and cheaper) alternative in the kid brother JCB Midi. This is still a fabulous present with the box measuring in at a substantial 38cm across. It’s a brilliant alternative to the 4CX and also an excellent companion for anyone looking to start their own mini backyard construction site!

If you’re not quite ready to commit to the mighty 4CX, Bruder do have a smaller (and cheaper) alternative in the kid brother JCB Midi. This is still a fabulous present with the box measuring in at a substantial 38cm across. It’s a brilliant alternative to the 4CX and also an excellent companion for anyone looking to start their own mini backyard construction site!

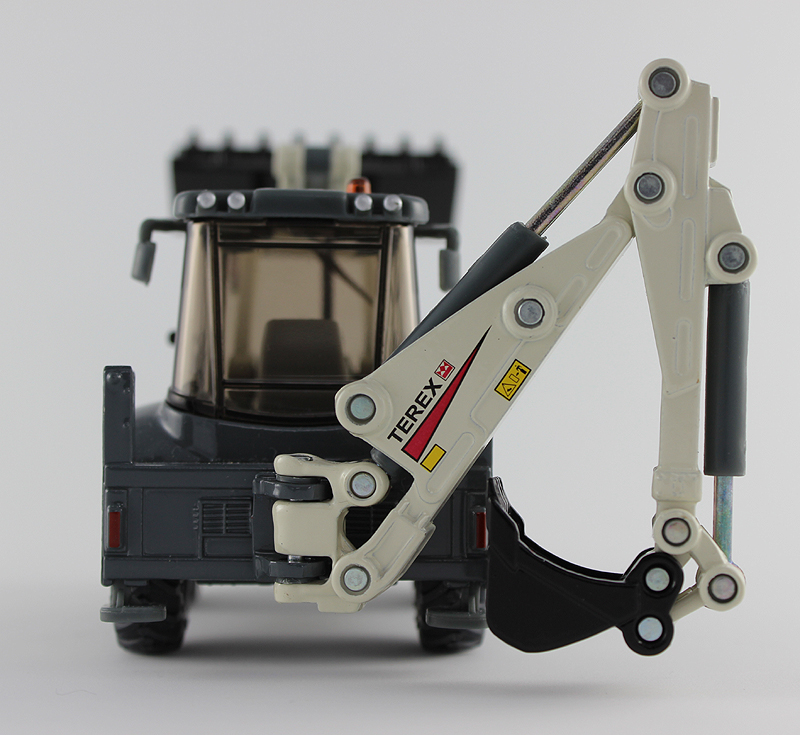

Now, what to get the older kid that has (mostly) grown out of garden excavations, but still loves diggers? Fortunately, Britains Toys have the answer in their terrific JCB 3CX model digger. We call this a ‘model’ as it’s mostly made of die-cast metal (apart from the cab). This means it’s ideally suited to display and more gentle indoor play. Older kids, teenagers and adults will all appreciate the authenticity of this toy digger; it’s a much more faithful replica than those previously mentioned. It can be posed in a variety of ways due to its moving buckets, boom, stick and even front axle. It makes a great desk toy or display piece.

So there we have it! A toy digger for fans of all ages, and you birthday gift and Christmas present problem solved.

Diggers, especially in the USA, are sometimes called backhoe loaders. In the UK the digger is often referred to simply by its iconic brand name, the initials JCB.

Diggers, especially in the USA, are sometimes called backhoe loaders. In the UK the digger is often referred to simply by its iconic brand name, the initials JCB. The massive US corporation Caterpillar Inc is synonymous with tracked vehicles.

The massive US corporation Caterpillar Inc is synonymous with tracked vehicles.

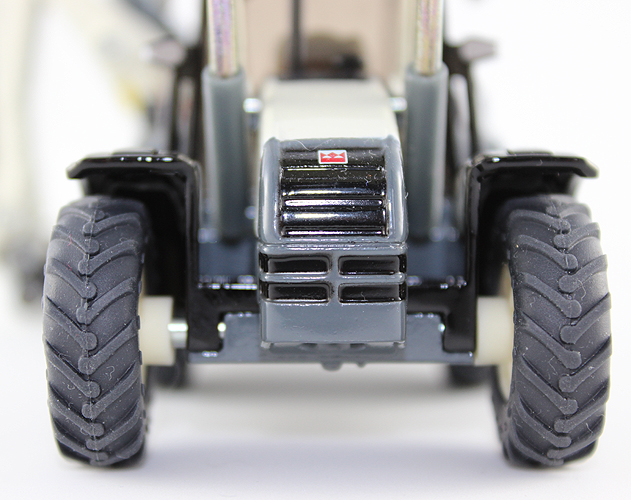

Excavators have just one arm at the front of the cab. The arm is made up of two sections called the boom and stick with a bucket at the end. The cab is mounted on a revolving platform with either tracks or wheels beneath.

Excavators have just one arm at the front of the cab. The arm is made up of two sections called the boom and stick with a bucket at the end. The cab is mounted on a revolving platform with either tracks or wheels beneath. The bulldozer developed from the farm tractor, its use first becoming widespread in America from the 1920’s. The first commercial bulldozer was the Caterpillar Sixty Horsepower, or Cat 60, developed by Holt in California. Holt subsequently merged with Best in 1925 to form the now legendary Caterpillar Tractor Company.

The bulldozer developed from the farm tractor, its use first becoming widespread in America from the 1920’s. The first commercial bulldozer was the Caterpillar Sixty Horsepower, or Cat 60, developed by Holt in California. Holt subsequently merged with Best in 1925 to form the now legendary Caterpillar Tractor Company.